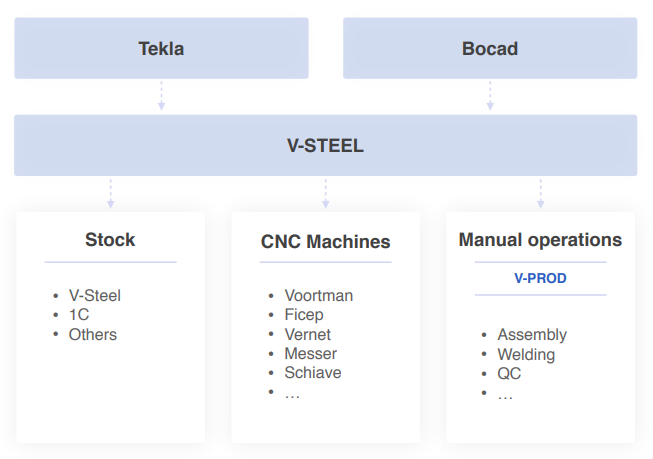

V-STEEL is a production management software. It was developed to optimize production management for companies in the metal sector.

V-STEEL allows you to optimize all production processes. It is compatible with any digitally controlled machine, and allows real-time monitoring of all production flows

nomenclature and details' geometries

and costs

Assembly, Welding...

and its parts (beams and plates)

Automatic, Semi-automatic or Manual

parts and assemblies visualization

in real time

in manual or automatic mode

V-Stock

You can import a nomenclature generated by Tekla or Bocad software (Excel or IFC). When importing, you can attach to each of the parts and assemblies their drawings generated by the design office, as well as other informations such as painting surfaces, weights, execution class...

After importing a contract, you get the following information with a single click:

Quantity of required materials for each profile and sheet

production time calculation for each machine

required consumables

For each detail, we have the possibility to have a quick visualization of details and assemblies, and if necessary the possibility to display the graph with more details.

V-STEEL has its own algorythm for Bars nestings. It allows you to create your nestings optimizing material and production times, then if necessary create an order for material, if your available stock is not enough.

For the Plates nestings, V-STEEL fully integrates the Act/Cut Software of the company Alma. Act/Cut allows you to automate Oxycut, plasma or laser technologies, including bevel heads or mixt machines (drilling, milling…)

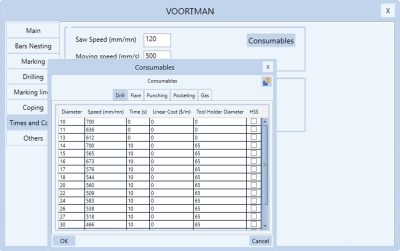

For each machine, the user has a variety of parameters, allowing to estimate with a precision less than 10% the different production times. Thus the user can choose on which machines to send the different jobs, in order to balance the workload on each of the machines.

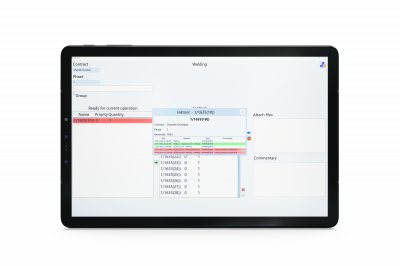

The V-PROD software is to be installed in the workshop (PC or tablet). This software allows the different manual workstations to have a preview of available assemblies or details, and update their production progress. If necessary, users can also access to details history, in order to identify faster existing problematics.

V-CNC Manager is installed on CNC machines (when possible), or on a PC/tablet near the machine.

There are three working modes:

If the machine has this possibility, no manipulation from operator is necessary

If the machine does not have the possibility to send production information, the operator must manually validate the nesting after cutting.

Same as Automatic mode, but a validation from operator is required.

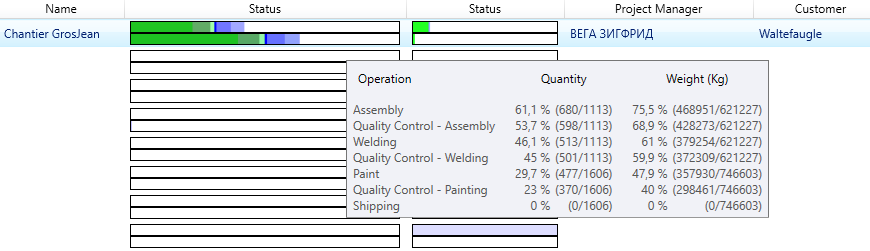

From the main screen you can see the progress of contracts.

You also can have an overview of advancement on 3D model. Colors for each operation are defined in a specific user menu

V-STEEL has its own stock management module, V-STOCK.

However, if you want to continue using your current stock software, it is easily possible to connect V-STOCK to it thanks to its connection module.